Serving Chicagoland Since 1968

Our New Location

Drummond Industries is Chicagolands premier choice in custom injection molding. We recently built a new 50,000 sq. ft. facility conveniently located in Bensenville IL, just outside of O’Hare Airport. Our new plant holds 20 injection molding machines, multiple options of auxiliary equipment and an in house tool room. With over 5 decades of processing experience, Drummond is the right choice.

24 Hours a day, 5 Days a week

Since 1968

Drummond, a family owned business, has been meeting and exceeding our customers expectations. We know that our reputation is only as good as our last shipment.

Facility Capabilities

Drummond proudly offers the latest technology and machinery for your business’s plastic injection molding needs. Whether you have a new project, an existing line or are ready to shop a better price on production costs, our team is ready.

High Quality Plastic Injection Molding In Chicago

For more than five decades Chicagoland businesses have trusted Drummond Industries, Inc., to be their go-to plastic injection molder. As a family-owned business, we take pride in working closely with our Illinois neighbors to deliver high-quality parts in a timely manner.

We can handle everything from prototyping to mass assembly from our modernly equipped, 50,000 square foot facility. Whether you’re looking to develop new products or improve plastic part production, our team is here to help.

Parts Manufacturing

Reliable Plastic PartsManufacturing

We can handle all sizes of custom molded plastic parts manufacturing from prototypes to high-volume. Our team will be with you every step of the way.

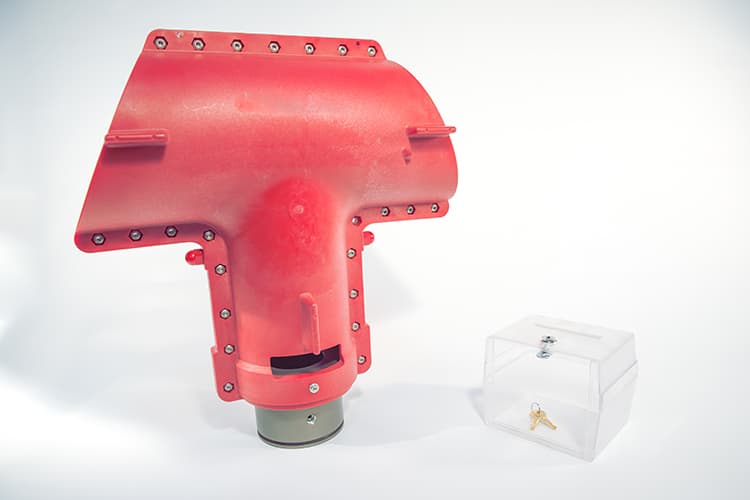

Plastic Injection Molding

High-quality plastic injection molded products designed and produced to meet your business needs.

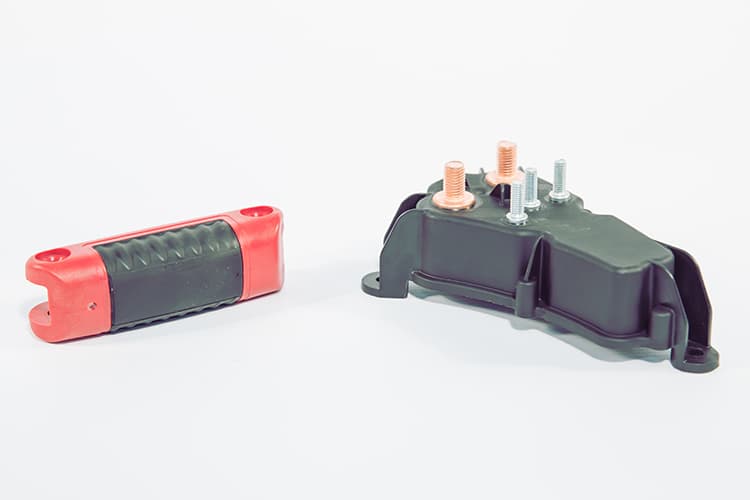

Insert Molding

Reduce assembly times and labor costs with integrated components through insert molding.

Part Assembly

Take advantage of our parts assembly and packaging services to reduce your production time.

Plastic Part Decoration

Add personalized branding through our parts decoration services, done in-house and customizable.

Ultrasonic Welding

Our plastic ultrasonic welding connects two parts to create stronger, more reliable bonds.

1968

Year Established

20

injection molding Machines

50+

Years of Experience

50,000

Square Foot Facility

On-Time Production

We understand the importance of maintaining a production schedule that you can count on, and our team is dedicated to getting the job done with the highest standards.

Dedicated To Your Project

Our team works hard to meet all deadline demands and provide the best service possible.

- 24-Hour Manufacturing, 5 Days A Week

- Office Hours – Monday – Friday, 7 am – 3 pm

Our Guarantee

“I know that Drummond’s reputation is only as good as its last shipment.”

-Matthew Gieser, President

Contact Us

Testimonials

Plastic Injection Molding

Resources & Media

Plastic Welding & Vehicle Design

In today’s fast-evolving automotive and aftermarket industries, the demand for cost-effective, high-quality, and customizable components

Custom Plastic Parts Vs Off-The-Shelf Products

In the world of manufacturing, choosing between custom plastic parts and off-the-shelf products can be

7 Design Considerations For Plastic Injection Molding Retail Displays

Designing effective retail displays with plastic injection molding involves understanding critical factors. At Drummond Industries,